Outdoor patio cushions take a beating from the elements. We are all faced with the decision to either purchase new or to recover your outdoor cushions. Unfortunately the cost to replace cushions is high. After thinking about it, I decided to put my sewing machine to good use a take a shot at recovering the cushions.

I would love to tell you this was a quick and easy project 🙂 , but the truth is, it took me a few days to complete eight cushions. There are some simpler ways to sew patio cushions, but I really liked the ones with piping. I also used a durable thick outdoor fabric and added zippers, so they would be easy to wash. Here is the process I used to tackle this project.

You are watching: How To Recover Your Outdoor Cushions For Your Deck or Patio Furniture

TOOLS & MATERIALS

This post contains affiliate links, which means I make a small commission at no extra cost to you. See my full disclosure statement here.

- Sewing Machine (I have an old Kenmore)

- Heavy Duty Needle

- Zipper Foot (should come with your sewing machine)

- Piping Foot (optional)

- Outdoor Thread

- Outdoor Fabric (two colors)

- Needle (for hand sewing)

- Seam Ripper

- Fabric Scissors

- Strait Pins

- Piping or Cording (I used outdoor type)

- Stapler (you could use pins, I found the stapler much easier)

- Flat Screw Driver & Plyers (to remove staples)

- Clear Acrylic Ruler

- Fabric Marking Pen

- Iron & Ironing Board

- Extra Bobbins (optional)

- Zippers (I reused the old cushion zippers)

- Foam (I reused the foam from my old cushions )

ABOUT THE FABRIC

The fabric on my old cushions was much thinner and pliable. I chose to purchase a fabric that was heavy duty, capable of being used in a wet environment. This fabric might be a little more difficult to work with than your average outdoor fabric, but for good reason. It is vinyl on the back side and canvas on the face side. I am very pleased with the weight, quality and price of this material.

When I tested it to see if it was waterproof, the water beaded up and did not soak in. Then when I dried it off, there were no water marks. It is suppose to be waterproof, mold resistant and 100% polyester. I’m not sure how it holds up to the sun’s UV’s, but I will post an update after a while to let you know. I ordered 10 yards and it came in a solid piece. I only used about 8 yards for 8 cushions.

UPDATE: After leaving them out in a heavy downpour, they did get wet inside.

I was able to make 4 cushion sets (8 total cushions) for the price of 1 set and I am confident that my cushions are much higher quality.

DECONSTRUCT YOUR OLD CUSHIONS

I wanted to use the old cushions as a pattern for the new ones, so I carefully deconstructed one bottom and one top pillow. I also removed and used the old zippers in the new cushions.

To remove the zipper, use a seam ripper. Start in one corner, pull the fabric apart and find the thread. Then use the seam ripper to cut the thread. When you get one corner open, you can pull on both sides of the fabric to finish tearing the threads.

Once I removed the zipper, I pulled out the foam from inside the cushion and set it aside for my new cushion covers. Then I finished taking apart the panels of fabric. I removed the extra threads and ironed the old fabric.

I also kept the old piping as a guide to measure out my new.

MARK AND CUT YOUR NEW FABRIC

Lay your old fabric on top of the new and cut around it to create your new panels. Then iron out the wrinkles. If you are using the same fabric I used, you will need to be careful to iron on the canvas side of the fabric. The back of the fabric is vinyl and will melt if you place an iron on it. Also, don’t leave the iron in one place for too long or it will also damage the fabric.

Next, lay your fabric on a flat surface and mark your seam allowance. My seam allowance was 3/8″. I used a clear acrylic ruler to mark my seam on the back of the fabric with a sharpie ultra fine marker. Just be sure you are on the back side of the fabric.

You’ll need to iron the ends of your largest piece of fabric over for your zipper installation.

CUT & SEW YOUR PIPING

Read more : What to Put in Outdoor Planters Besides Flowers

I used a lighter cream colored fabric for my piping. Using your clear ruler cut 2 1/4″ wide strips of fabric. If your piping length is longer than your fabric strip, combine 2 strips by stitching the corners together.

Then using a cording foot or zipper foot, stitch the fabric strips around your piping. Then go back and cut the seam allowance to 3/8″.

Don’t back stitch the ends of your piping as you will need to finish them off later.

This is a good video on how to sew piping.

ATTACH YOUR PIPING TO THE FABRIC

Take one of your end pieces of fabric, right side facing up, and lay your piping along the bottom edge of the panel. The nice side of the piping is in towards the center of the fabric and the seam allowance is at the edge.

Using a zipper foot, start sewing your piping to the fabric. You want to sew really close to your piping for a cleaner look. I always start along a strait edge and work towards the curve.

Also, don’t sew the end of your piping down, since we need to close it later. Start in a few inches from the edge.

When you get the the curve, snip the piping at the seam allowance, so the needle can move along the edge smoothly. Sink the needle down and then raise your presser foot to turn the fabric.

Once you’ve sewn almost all the way around, stop about two inches before the end of the piping. Back stitch. Then remove the fabric from the sewing machine.

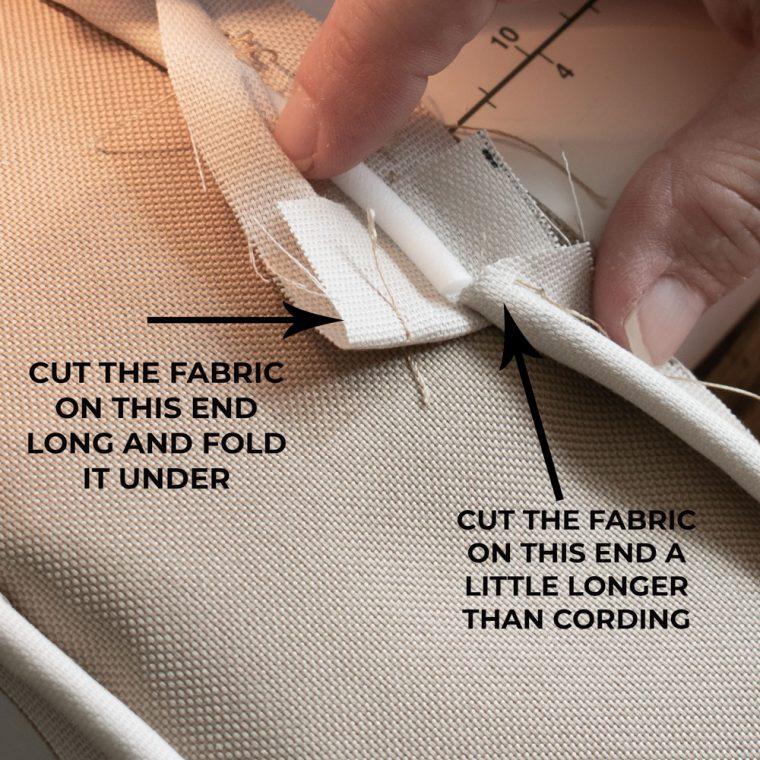

Fold your fabric back from the cording on both sides. Line the cording up, and cut it, to remove the extra.

Then cut off the extra fabric from the last side of the piping fabric you sewed, leaving enough extra to fold the end of the fabric under. Now cut the other side of the fabric just a little longer than the edge of the cording. Fold one side of the piping under and place it over the edge of the other side.

Put the piping back in your sewing machine and stitch the finished piping down.

Don’t forget to back stitch each end. You need to repeat this process for both end pieces of fabric.

ADD YOUR ZIPPER

Take your main fabric panel with the ironed seam allowance on each end and place the zipper under it. Be sure the right side of the zipper and fabric are facing up. Line up the ends of the fabric and allow a little space for the seam allowance.

Then using a zipper foot, sew along one edge of the zipper. Be sure to back stitch at the beginning and end of the zipper.

Read more : Should I Use 12 Or 14 Gauge Wire For Outlets?

Now with your zipper closed, stitch up the other side about two inches. Be sure the fabric underneath is pushed out of the way, so it doesn’t get caught in the needle. Back stitch to lock the thread at the beginning and end, then remove it from the machine.

Open the zipper all the way, move the fabric underneath out of the way, and finish sewing up the rest of the zipper. Be sure to back stitch at the beginning and end.

ATTACH END PANELS

Turn your fabric inside out. Using a stapler attach one of the end panels to the main panel along the seam allowance. I found it was easier to hold the stapler upside down and press it all the way to the piping, then staple.

Start stapling at the zipper corner, since this is the most difficult area to line up. Then work your way around the panel.

Take your stapled panel back to the sewing machine and begin to stitch your seam. I always start in the middle of a strait area and then work around the corners/curves. I use my zipper foot and sew as close to the piping as possible. This will give you a better finish.

When you get to the zipper, if your fabric is too thick, you can back stitch and remove it. Then start again, just after the zipper. Be sure to go back and hand sewed the zipper part afterwards.

I highly recommend this video before you start to sew your end panels. It will help you understand the technique for sewing thick fabric with curves.

When sewing around the curved areas, snip slits in the seam allowance so it will lay flat for you. If you sew the curves slowly, it will be easier for you to control.

Next, open the zipper, before you attach the other side panel. Otherwise you won’t be able to turn your fabric right side out. Then attach the other end panel with the stapler. Now sew the other end panel.

Next, remove your staples. I used a flat screw driver and pliers to do this.

Finally, turn the cushion right side out. You want to inspect your piping at this point. Sometimes, if you are not close enough to the piping with your zipper foot, the piping is not tight to the fabric and doesn’t look good. If you have this problem, make note of where it is and turn you cover inside out and stitch that area again. Making sure to back stitch at the beginning and end of the area.

INSERT YOUR FOAM

Fold the foam in half and slide it through the zipper opening. Then reach in and around the foam to adjust it into place. Close your zipper and your done!

ACCESS MY FREE LIBRARY & JOIN THE COMMUNITY

I’m always up to something new and sharing my best DIY tips along the journey. I also love designing free printables to go along with my projects. For instant access to my library and regular updates on blog posts, subscribe at the top sidebar or at the bottom of this post. You’ll receive a welcome email with the password to enter the library along with regular updates on my most recent blog posts.

FOLLOW ALONG ON PINTEREST

Do you like learning budget friendly ways to spruce up your home? Follow me on PINTEREST. Did you know that you can hover over the images below, click on the red Pinterest circle and save it to your OUTDOOR SPACES or DIY PROJECTS BOARD on Pinterest? It’s so helpful to Pin It now and save it for later, when your ready to start your project.

I hope this tutorial helps you recover your outdoor cushions! Thanks for stopping by!

RELATED

Source: https://gardencourte.com

Categories: Outdoor