heavy duty professional resin floor paints coatings and screeds for kennels, catteries and animal pens

There are a number of different solutions for floor finishes in dog & puppy kennels, catteries and animal pens.

- Best outdoor vs. indoor TV antennas: How to choose the one that’s right for your home

- The Best Outdoor Furniture of 2023, Tested and Reviewed

- Golden Artist Colors, Inc. | Murals (Exterior)

- Amazonian tree with human-sized leaves finally gets ID’d as new species

- Best Night Vision Security Cameras – Read This Guide Before You Buy One

The cheapest alternative is to give the concrete slab a brushed finish when it is first laid and leave it like that. The downside is that concrete is slightly porous and the older the slab gets the drier and more porous it gets. So water and animal urine get absorbed by the top surface of the concrete. It then becomes difficult to clean and will start to smell.

You are watching: Floor Finishes for Dog & Puppy Kennels, Catteries and Animal Pens

A resin floor paint for the concrete slabs in dog & puppy kennels, catteries and animal pens, is the next solution up. A ready-to-use straight out of the tin concrete paint is easy to apply by brush and provides a coating that stops moisture being absorbed by the concrete. Once applied and dried it is easy to clean and hose down. Like all resin floor finishes it provides a hygienic finish, which will not support bacterial or fungal growth. An example product would be Resucryl

The only problem with a floor paint is that it is more suited to domestic applications; it doesn’t last very long in heavy duty conditions and can get scratched and chipped. When this happens the concrete beneath becomes exposed and can absorb water and urine, leading to smells. It will also show wear faster than other finishes and needs to be re-applied /re-coated relatively frequently, e.g. every 2 years.

Integral floor drains should be a part of your kennel design from the outset. Channel drains, often referred to as ‘aco’ drains, slot drains or inset floor gullies, ensure that areas can be cleaned and hosed down and the grey water (dirty water from cleaning) can be removed easily. Ensure that finished floors are laid-to-falls, i.e. graded down towards the drains.

Slip-resistant vinyl sheeting is good until it gets damaged, either at the edges, welded joints, coved skirtings or even the sheetss themselves getting pierced. Once this happens, liquid gets underneath the sheets, which is impossible to clean without stripping out the sheeting. This is similar for other sheet, panel and tile materials.

Ceramic tiles such as quarry tiles are an expensive option and even though the tiles themselve perform excellently, the grout joints are slightly porous and gather dirt over time.

Read more : How To Keep Bugs Away From Cat Food!(27 Amazing Ways)

Thicker coatings can be used; such as high-build or self-levelling resin floor coatings. These coatings are much harder to damage through to the concrete and much more durable. They are also more expensive. They can be laid relatively easily with rollers or squeegees and can incorporate aggregate to give a non-slip finish. Care needs to be taken when specifying to ensure that the coating is resistant to your cleaning regime in terms of specific chemicals and water temperature. Some coatings are not tolerant of high temperatures, so if you use hot water or steam to clean then you should check this. Resucoat HB epoxy resin and Resupen WB polyurethane resin are both robust coatings. If the floor you are coating is asphalt or bituminous you will need to use a material like Resudeck.

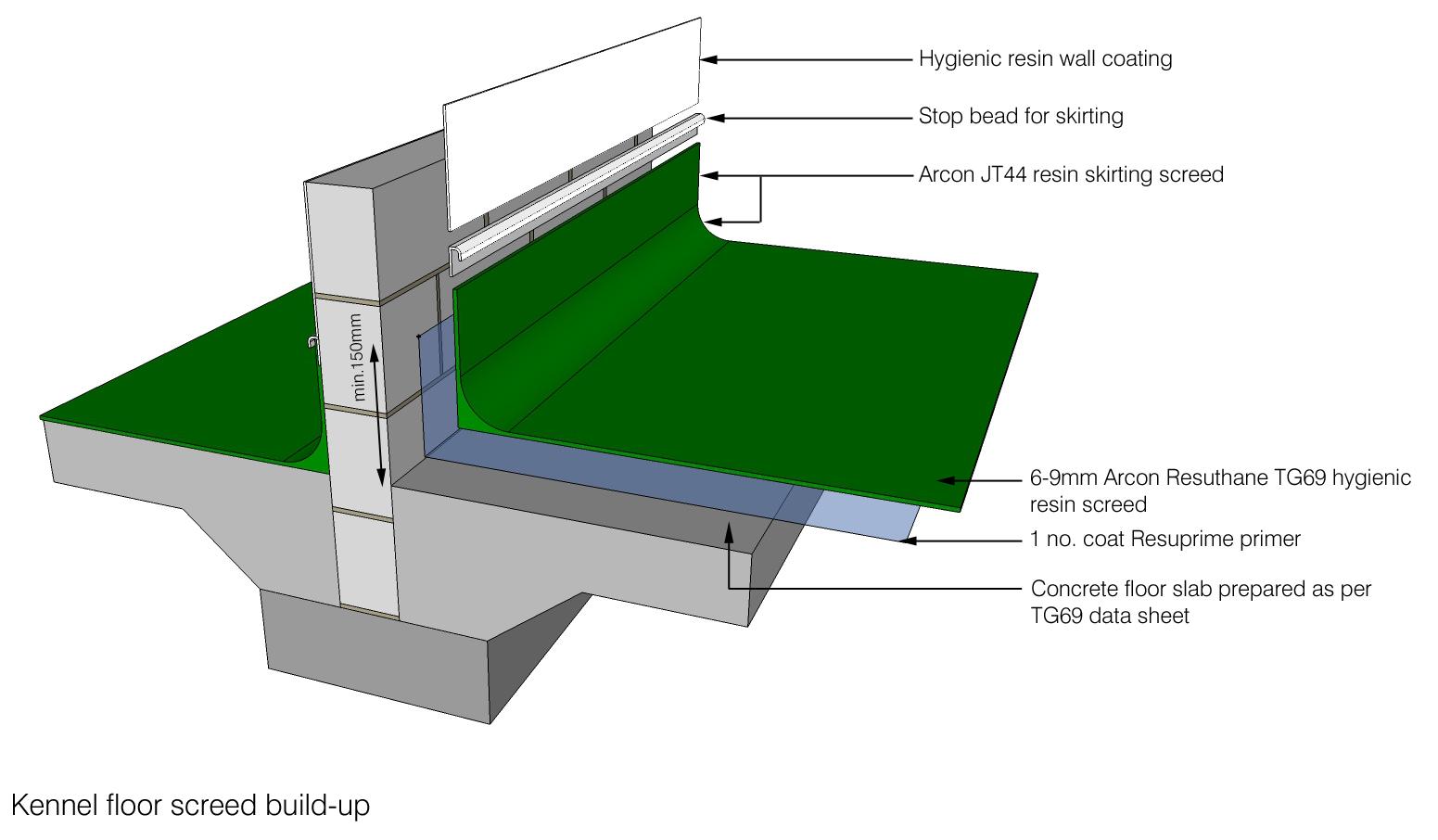

The best floor finish for a kennel or cattery in our opinion, but also one of the costlier options, is a resin floor screed. Laid at 6-9mm in thickness using a trowel they give a highly durable and robust finish that will resist scraping and impacts. Like all resin floor finishes the screeds give a seamless and hygienic surface that will not support microbe growth. Screeds are usually through-colour and highly chemically resistant, so they will resist chemical attack from animal urine and excrement as well as cleaning chemicals. If you are cleaning with steam or hot water you are likely to need a polyurethane screed rather than an epoxy screed, but it is always best to review on a project by project basis. Example products are Resuthane TG69 and Pumadur HF, also see the diagram below. Although the upfront costs are higher than some other floor finishes, it can be economical in the long term when you factor in the higher maintenance costs and shorter life-span of other cheaper finishes.

Resin screeds can incorporate integral skirtings that curve up the walls to a stop-bead. Example products are Resuthane JT44 (formerly Resuthane JT40), Pumadur CG or Pumadur WR. This is advantageous because it eliminates a junction between skirting and flooring, which can be difficult to clean effectively, and over time can accumulate dirt and support microbe growth. This will also make hosing down areas easy, with limited potential for water to leak into joints and damage floors and walls over time. Again the integration of integral inset drainage at design stage is important to make cleaning as easy as possible.

There are a large number of proprietary (pre-made) purpose built kennel systems that incorporate, walls, doors, gates, outdoor access, fencing and outdoor enclosures. It is important that any of the materials used are robust and do not absorb moisture. Timber will absorb urine and grey water (dirty water from cleaning). Even if it is varnished or coated, when this flakes it will expose the unprotected timber.

When using laminate systems, check what the substrate is. If the laminate is on to chipboard or regular MDF then when the laminate chips or the board edging comes loose then liquid will be soaked up by these absorbent materials. This is not only impossible to clean and will lead to bad smells, it will cause the boards to expand and ultimately break apart. Look for WBP plywood (which has ‘water and boil proof’ glue and is suitable for exterior use) and MR MDF (moisture resistant medium-density fibreboard). If you are planning to hose down the walls then the best option is a solid grade laminate (sometimes referred to as SGL), or GRP or plastic panels.

Where you have exposed blockwork walls it is important to seal them, because they too are absorbent and will smell over time after water and urine has soaked in. The blockwork and mortar joints can be painted with a non-absorbent coating such as gloss paint or resin wall coatings, or by fixing sheet materials to the wall. The advantage of paint and resin wall-coatings over sheet materials such as uPVC wall cladding sheets, such as Whiterock, is that it is seamless so there are no joints that could let liquid in behind it.

Example kennel floor & wall finishes:

SEE ALSO:

SEE ALSO:

Resumprime product data sheet

Resuthane TG69 product data sheet

Resuthane Floor Screeds Colour Chart

Pumadur Floor Screeds Colour Chart

Resin Wall Finishes Colour Chart:

Source: https://gardencourte.com

Categories: Outdoor