Plywood is one of the most popular and useful products on the planet.

It’s a versatile material that can be used for flooring, roofing, DIY projects, to make furniture, and much more.

You are watching: 11 Best Plywood Alternatives (2023 Guide)

But what if you don’t have any plywood laying around and your local store is out of stock?

Luckily, there are plenty of great plywood alternatives you can use! Here are some of the most common.

Best Alternatives to Plywood

1. Medium Density Fiberboard (MDF)

Medium density fiberboard, otherwise known as MDF, is a material that’s similar to plywood in numerous ways.

But unlike plywood, MDF boards don’t utilize wood veneers. Instead, it’s made of loose wood fibers that have been bound together with chemicals.

And because of the way it’s constructed, there’s no woodgrain.

One of the key reasons why this material is preferred is because it doesn’t expand and contract with temperature fluctuations.

Plus, if you’re used to working with plywood, you should have an easy time working with this material as well.

Additionally, you can sand, apply adhesive, and paint or stain it with no issues. It’s also moisture-resistant along with being easy to cut and shape.

If you’re environmentally conscious, you should love MDF, as it’s made of recycled materials and manufactured in a way that doesn’t leave a big carbon footprint.

But it’s not better than plywood in every respect. Specifically, plywood is more durable than MDF.

The good news, however, is that its durability can be improved. Just apply a special strengthening wax to your MDF and its structural integrity will be boosted substantially.

2. Polyurethane Foam Board

You’re probably familiar with polyurethane—the resin that’s applied to a range of materials to make them stronger. Polyurethane foam board is a popular plywood alternative largely because it’s more durable.

It’s lightweight too, and if you get fiberglass-reinforced polyurethane foam boards, you can expect these to be both strong and long lasting.

Reinforced polyurethane foam board is used for a variety of things, and its versatility is another reason why it’s sought after.

But one downside is that this material isn’t all that visually appealing. Yes, a lot of polyurethane foam boards have a decorative outer later, but this doesn’t fit with other surfaces well and is nearly impossible to paint over.

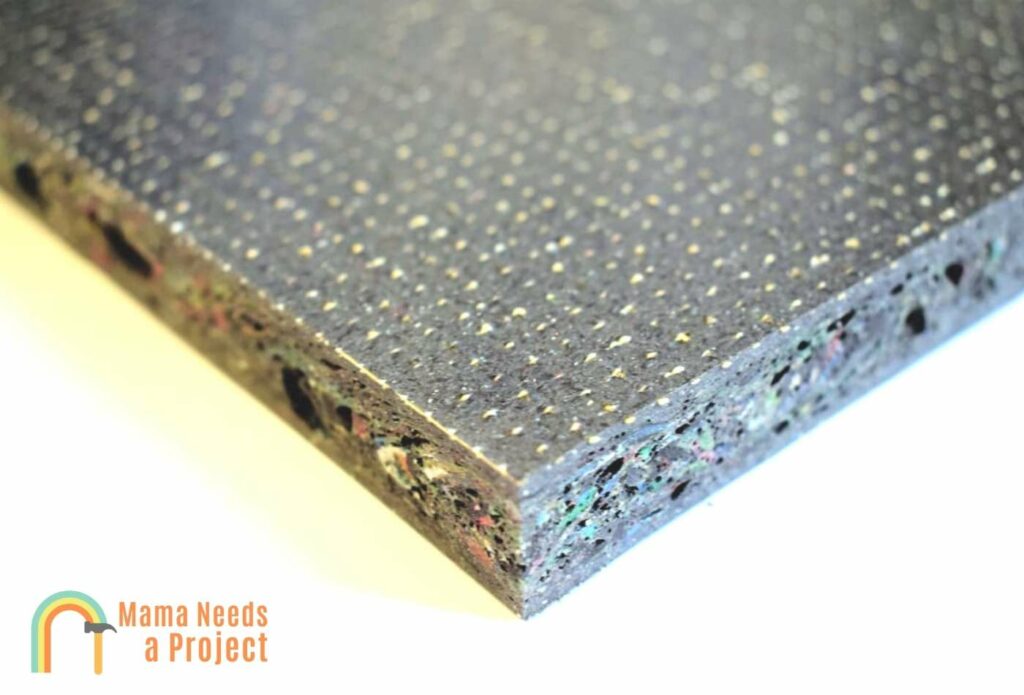

3. Particle Board

The most affordable option by far is particle board. And because of the way it’s constructed, it’s the most lightweight option as well.

Specifically, wood particles are condensed to make particle boards, and the manufacturing process is largely what makes this material smooth and perfect for flooring reinforcement.

This material comes in numerous thicknesses and densities, so it’s much more versatile than some of the other materials I disuse later.

It’s also easy to cut, and you won’t have a hard time getting adhesives to stick to it. In fact, it’s often glued to linoleum, tile, and hardwood for reinforcement.

And since it’s free of formaldehyde and made with numerous eco-friendly components, this is a staple in green homes.

The downsides are it’s not as strong as other materials, and it’s not the most visually appealing material. Furthermore, painting particle board can be difficult.

Check out this plywood vs particle board comparison for more info!

4. Oriented Strand Board (OSB)

Read more : Can Outdoor Cushions Be Thrown in the Washer?

If you don’t want to use plywood and you’d rather pass on MDF, you should consider oriented strand board or OSB.

Like MDF, this board is constructed with wood chips. But how the wood chips are arranged is what mainly distinguishes OSB from MDF. With OSB, the wood chips are arranged to create a uniform surface; MDF, on the other hand, is made of wood pieces that have been randomly arranged.

OSB comes in a variety of sizes and thicknesses, and some versions are very rigid whereas others are much less rigid.

This is a strong, water-resistant board, one that’s long lasting and usable for a wide variety of construction projects. It’s an eco-friendly option too, one that’s more affordable than plywood.

5. Solid Wood

Of course solid, or natural, wood needs to be included on a list of plywood alternatives. When I say “solid wood”, I’m referring to wood that hasn’t undergone processing of any kind.

There are numerous benefits associated with using solid wood instead of plywood. For example, it’s much more attractive; it’s a lot sturdier too.

Plus, it can be altered in numerous ways, by shaping, cutting, etc.

One of the obvious downsides associated with solid wood is it’s not the most eco-friendly option; think of how many trees must be cut down to get enough solid wood to make a floor or a row of cabinets. Also, because plywood doesn’t weigh a ton, the weight of real wood can be tremendous on some projects.

Solid wood is also one of the most expensive alternatives, especially when you consider the cost of plywood.

Usually this kind of wood is chosen over plywood when price isn’t a concern and more reinforcement is needed.

6. EKO Ply

Doesn’t get more eco-friendly than EKO-ply. This is plywood alternative is made entirely of recycled materials.

It’s durable and longer-lasting, and large part because it’s moisture-, rot-, and corrosion-resistant. It’s also chemical-resistant, making it an ideal material for several industrial and commercial applications.

One downside is that it’s not the most visually appealing material, but it’s easier on the eyes than several other recycled materials.

While it may not be the best material to look at, it is easy to clean and maintain.

7. High Density Fiberboard (HDF)

We’ve already discussed MDF and OSB—now it’s time to talk about HDF. This is an engineered wood product that’s similar to MDF in numerous ways, but it’s much stronger and denser.

This material is made of exploded wood fibers that are compressed and bound; that’s where the strength comes from.

It’s often used to make solid wood furniture, and floor installers will put it down to temporarily protect their work.

And because no chemicals or glues are used to make it, this is an eco-friendly material. The binding agent in this material is lignin, which is an organic polymer.

Because of its durability, it’s more expensive than both MDF and plywood; in fact, it’s closer in price to solid wood.

8. Fiber Cement Board

Also known as fiber cement siding or just cement board, fiber cement board is a composite material that’s made of cellulose fiber, cement, sand, and water.

It’s a strong materials that’s used often for residential applications, and in addition to being easy-to-maintain it’s moisture-, rot-, and fire-resistant. It’s affordable too.

But one downside is it’s susceptible to mold growth, and it’s also heavier when compared to plywood.

That said, this material is ideal in areas frequently experience tornadoes and hurricanes, and that’s because it doesn’t blow away like aluminum and aluminum siding do.

And like most of the other materials discussed thus far, it’s made of sustainable materials.

9. Glass Reinforced Plastic (GRP)

Read more : OSHA Water Requirements: Are Employers Required to Provide Water?

This plywood alternative is what you get when you bind glass fibers with a polymer or plastic. Essentially, the glass fibers come together to form an extremely durable material.

And if your GRP is made with aluminum oxide, you can count on it to be extra durable.

This stuff is so strong that a 1/8-inch sheet is as strong 3/4-an inch plywood board.

In addition to being strong, it’s also corrosion-resistant and versatile.

The downside is it’s expensive. Plus, it can be difficult to find. But if you can get your hands on it, incorporate it where practicable.

10. Masonite

Masonite manufactures a pretty reliable plywood substitute. This hardboard is made of steam-cooked, pressure-molded wood fibers.

Often used to construct floors in theaters, this material can also be used in homes, specifically as paneling or partitions.

It comes in a range of sizes and it’s both strong and affordable. Another plus is that it resembles solid wood.

The downside associated with this material is it isn’t all that moisture-resistant, so you could face mold and mildew problems after installing it.

11. King StarBoard High Density Polyethylene (HDPE)

KingStarboard high density polyethylene (HDPE) is a popular plywood alternative that’s used mainly in humid climates because it’s moisture resistant. This quality also makes it great for a variety of marine applications.

For example, this material is often used to construct underground piping.

In addition to being water-resistant, KingStarboard HDPE is UV- and scratch-resistant as well. These qualities are a result of this material’s makeup and the manufacturing process that’s used to make it.

Because of these properties, KingStarboard HDPE is an expensive material; in fact, it’s one of the most expensive materials discussed in this post.

Pros & Cons of Plywood

Pro: Strong

One of plywood’s most attractive qualities is its strength. It’s resistant to dents and dings, and it’s strength largely comes from the materials and process and that’s used to manufacture it.

Pro: Stable

Plywood’s stability ensures it holds both nails and screws well. Plus, since it’s for the most part unaffected by temperature fluctuations, it won’t shrink or expand frequently.

Pro: Paintable & Stainable

Plywood is both paintable and stainable, and the same can’t be said for MDF. That said, neither painted nor stained plywood are more attractive than their solid wood counterparts. You can check out these methods to make plywood look good like by whitewashing it.

Pro: Used Indoors & Outdoors

Plywood can be used both indoors and outdoors, which speaks to its versatility. Other materials like MDF can be used both indoors and outdoors too, but plywood tends to be more reliable because of its composition and other factors. There are also a few ways to waterproof plywood that can be super handy.

Con: More Expensive

Plywood is more expensive than most of the other materials that can be used in its place. Its high price is largely a result of the components used to manufacture it. Also, its price is higher than other materials because it’s constantly in demand.

Con: Hard to Cut and Mold

Plywood’s durability may be one of its most attractive qualities, but it’s this quality which makes plywood hard to cut and mold. Therefore ,if you’re looking for a material that’s easy to shape, passing over plywood may be a smart move.

Con: Needs to Be Edged

Plywood can also a rigid and sharp material unless it’s properly edged. Often it’s laminated, or wood veneers are added, to make it smoother (and safer).

FAQs

What can I use instead of plywood for sheathing?

If you need a material for sheathing that’s not plywood, consider plastic, rigid foam, and cellulose fiber. Paper- and foil-faced boards should also be considered, along with diagonal boards and fiberglass-faced gypsum panels. The cheapest material for sheathing is OSB, followed by plywood.

What material is used instead of plywood?

Numerous materials can be used instead of plywood. For example, MDF, polyurethane foam board, particle board, OSB, solid wood, EKO ply, HDF, cement board, GRP, Masonite, and KingStarboard HDPE can all be used in place of plywood.

Is MDF board better than plywood?

In several respects, MDF is better than plywood. For one, it doesn’t expand and contract as the temperature fluctuates. Plus, it’s more moisture-resistant, easier to use, and made of eco-friendly materials. Where it loses out to plywood is in the durability category.

Final Thoughts

Although plywood is a versatile, affordable, and overall useful material, there are times when alternative materials are better.

There are plenty of great plywood alternatives you can use to complete your project whether you opt for high density fiberboard, particle board, or MDF boards.

Source: https://gardencourte.com

Categories: Outdoor